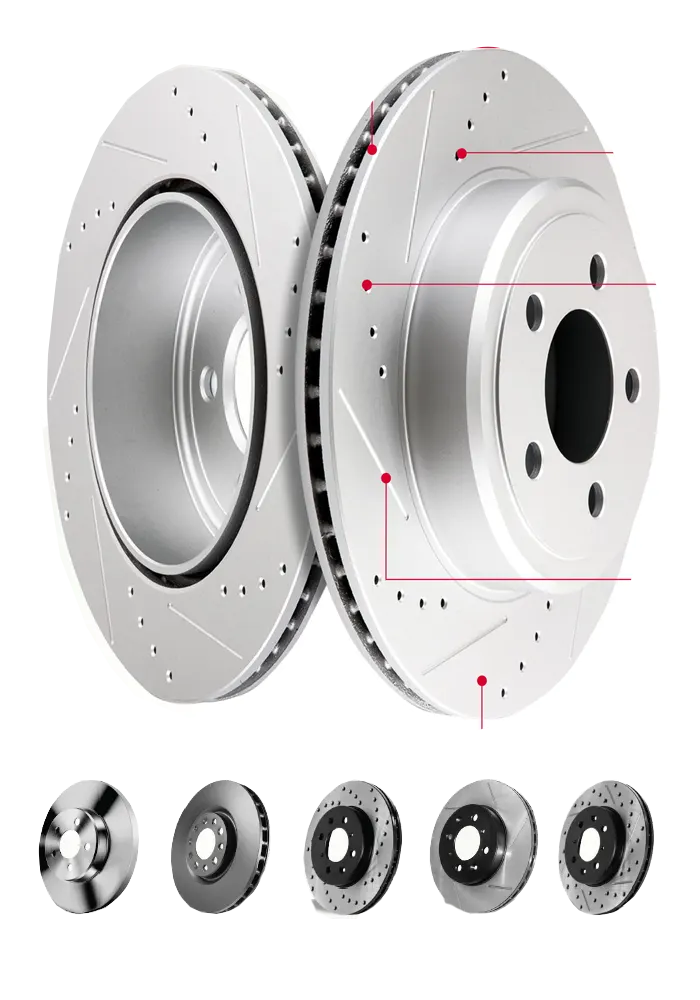

Disc Brake Rotors

- Precise Machining & Castings All Active rotors are reverse engineered from OEM samples. MACHINING SPECIFICARIONS: Rotor run out is within .0015 and Active tolerance specifcaticon is within 0.006 All rotors are mill balanced.

-

Beveled Drill Holes

Beveled and precision drill holes help keep rotors temperatures down during extreme braking performance.

UP TO 160 COOLER - Rounded Slots Slots keep a clear contect patch between the ped and the rotor by sweeping away gas and dust.

- Weather Resistant Coating All drilled and slotted rotors (except for hub rotor assemblies) are Weather Resistant Coated to helps shield and resist rust during normal operation.

Feature Benefits

- Centre-split core castings increase heat transfer and thermal efficiency, resulting in better beaking power and safety

- Tight machining tolerances for original equipment quality, fit and performance

- Quality guaranteed

Get The Most Out Of Your Brakes With Premium Active Rotors